Installation of Werever outdoor cabinets does not require previous cabinet installation experience. A basic knowledge of common hand tools is required, but extensive knowledge of carpentry is not necessary. Almost all of the projects in our photo gallery are of first-time installations. These projects are of either DIY installed projects, or with a hired a handyman or contractor. You can expect your first project to be successful with a minimal learning curve.

Special Installation Note: Please read this article: How to Have Straight Outdoor Cabinet Doors

Installation Instructions

PDF (554 KB)

Print / Download PDF installation instructions.

If you have questions, please call (813) 241-9701.

- Level (two levels, one long and one short, make installation easier)

- Drill (1/4 inch bit required to finish pre-drilled holes or drill new holes as needed)

- Phillips Head Screwdriver (2)

- Clamps (with rubber pads to prevent scratching the cabinetry)

- Dry erase markers (for marking anything on the material if necessary)

- Saw (either circular saw or table saw – to trim fillers and toe kick pieces)

- Carpenter’s Square

- Tape Measure

Leveling the Cabinets

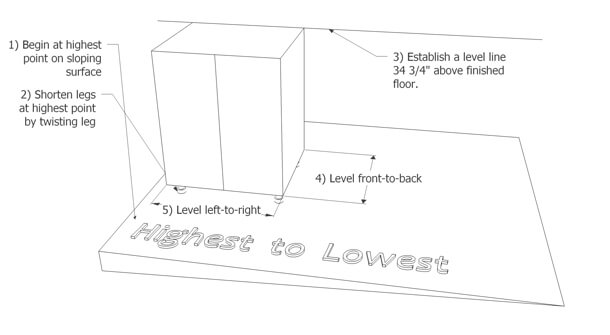

Level the cabinets by beginning at the highest point of the sloping surface. Shorten the legs at the highest point of the slope. Establish a level line at the countertop height. Level the cabinets front-to-back and left-to-right.

Level the cabinets by beginning at the highest point of the sloping surface. Shorten the legs at the highest point of the slope. Establish a level line at the countertop height. Level the cabinets front-to-back and left-to-right.

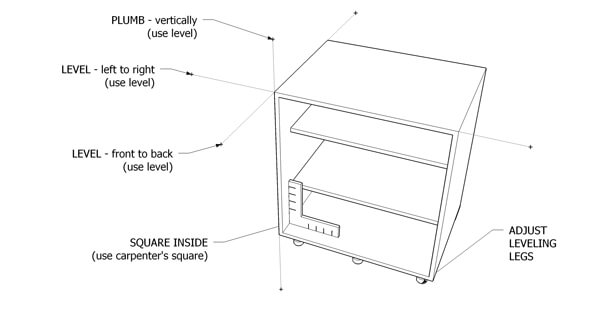

Plumb the cabinets vertically using a level. Level the cabinets front-to-back and left-to-right using a level. Check the inside using a carpenter’s square to make sure the cabinet is square. Make adjustments using the leveling legs.

Plumb the cabinets vertically using a level. Level the cabinets front-to-back and left-to-right using a level. Check the inside using a carpenter’s square to make sure the cabinet is square. Make adjustments using the leveling legs. Anchoring to Walls

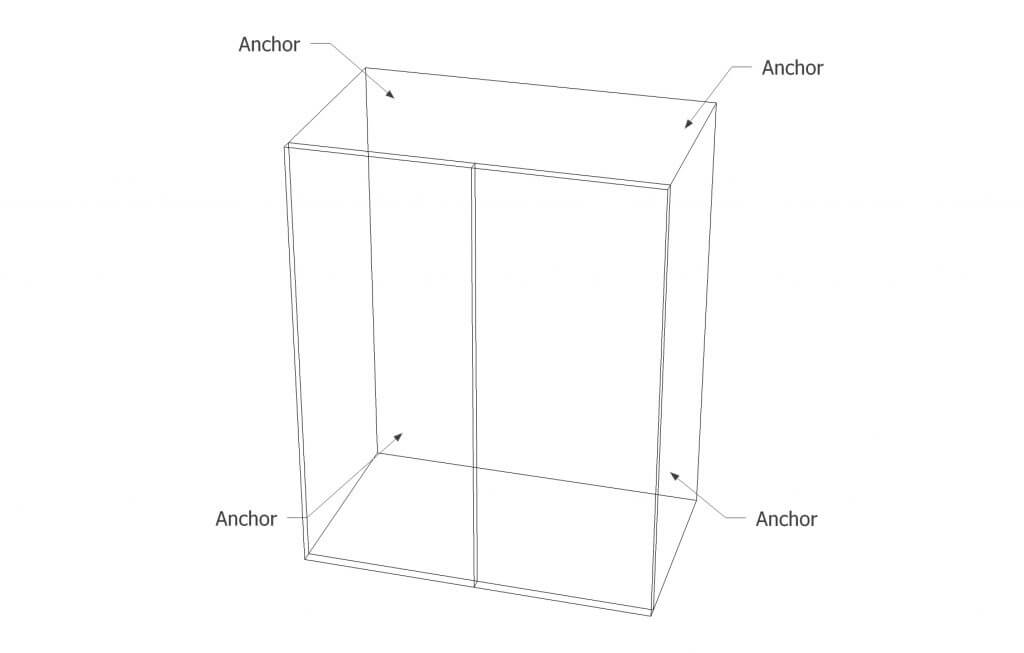

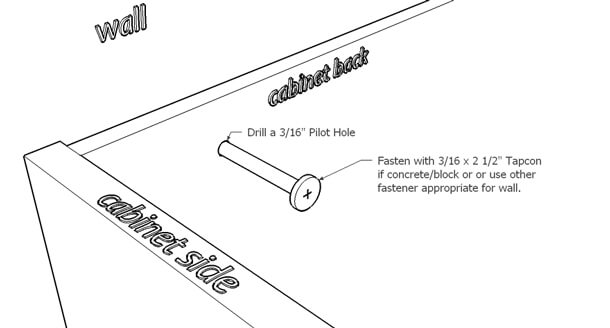

Once leveled, fasten cabinets to walls using common hardware (not provided). For concrete block or stucco walls, stainless steel Tapcon® fasteners are recommended. Two fasteners per cabinet are recommended for base cabinets, four fasteners are recommended for wall cabinets.

Fasten with 3/16″ x 2 1/2″ Tapcons if the wall is concrete or block. For other walls, use a fastener that is appropriate for your wall.

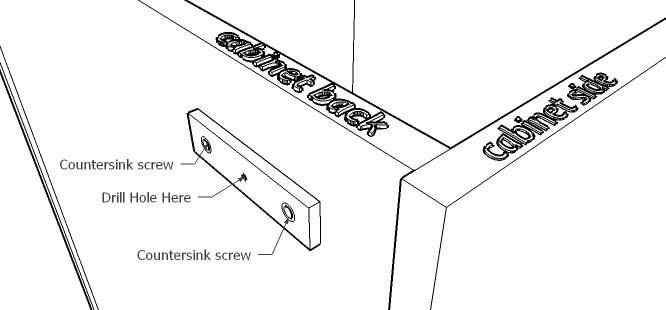

Fastening to Each Other

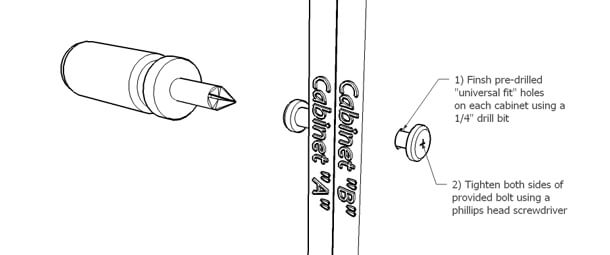

- Use clamps to hold the cabinets in place when drilling and attaching hardware

- If the pre-drilled holes don’t line up, that is a red flag that your cabinets aren’t level

- For some parts, pre-drilled holes do not exist. You will have to drill your own holes

Finish the pre-drilled holes on each cabinet using a 1/4″ drill bit. Tighten both sides of the provided stainless steel bolt using a phillips head screwdriver.

Finish the pre-drilled holes on each cabinet using a 1/4″ drill bit. Tighten both sides of the provided stainless steel bolt using a phillips head screwdriver. Countertops

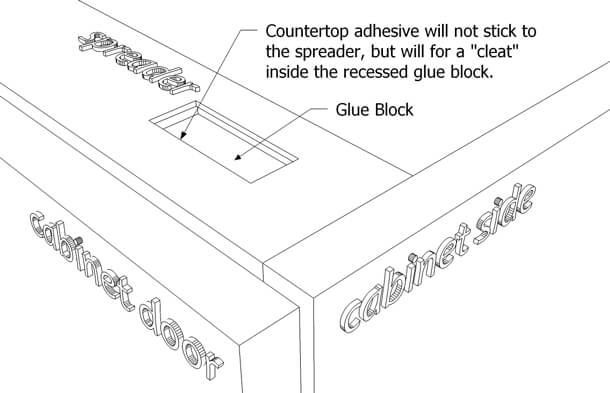

For a do-it-yourself project, a tile countertop is recommended. Professional countertop fabrication is recommended for granite, concrete, quartz (Silestone® or Zodiaq®), or solid-surface acrylic (Corian®) countertops. Cabinets feature special countertop installation aids.

Countertop adhesive will not stick to the spreader, but it will form a cleat inside the recessed glue block.

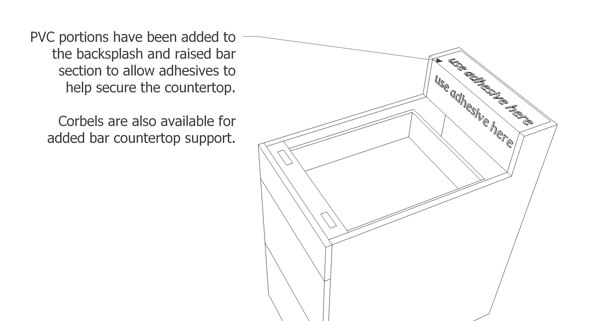

Gluable portions have been added to the backsplash and raised bar section to allow adhesives to help secure the countertop. Corbels are also available for added bar countertop support.

Cutting through Cabinets

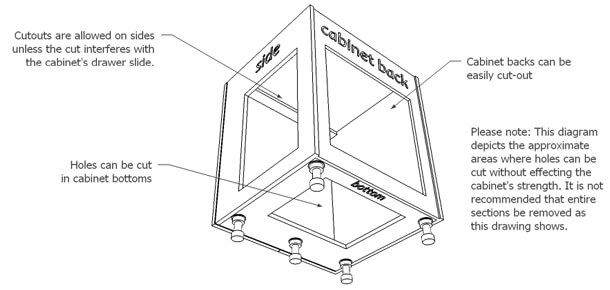

Holes can be easily cut in cabinet backs, sides, and bottoms for plumbing, gas lines, or electrical work using ordinary hand tools.

- Cabinet corners and joints should not be cut as that will alter the structural integrity and strength of the cabinet.

- Morse Hole saws are not recommended. The HDPE shavings (or saw dust) tend to melt inside these bits. A jig saw or paddle bit is recommended.

If necessary, holes can be cut in the sides, back, and bottom of the cabinetry. Do NOT cut through any of the structural seams of the cabinetry.

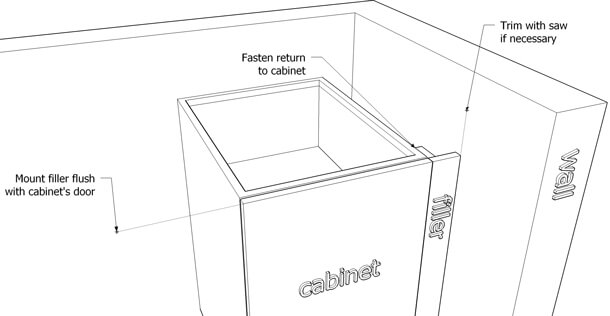

Fillers

Depending on your design, you might have fillers. And depending on your actual situation in the field, the fillers may require trimming.

- Fillers are secured to the neighboring cabinet by attaching the return piece using the supplied stainless steel bolts. Fillers will have the same pre-drilled pattern on the return piece that cabinets have.

- Fillers should be mounted so the face of the filler is flush with the neighboring cabinet’s door face.

- Fillers can be trimmed with a table saw (or circular saw) if necessary. You can cut the filler with an ordinary woodworking saw.

Fasten the return piece of the filler to the neighboring cabinet using the supplied stainless steel bolts. Be sure to mount the filler flush to the cabinet’s door. Trim the filler’s width using a saw if necessary.

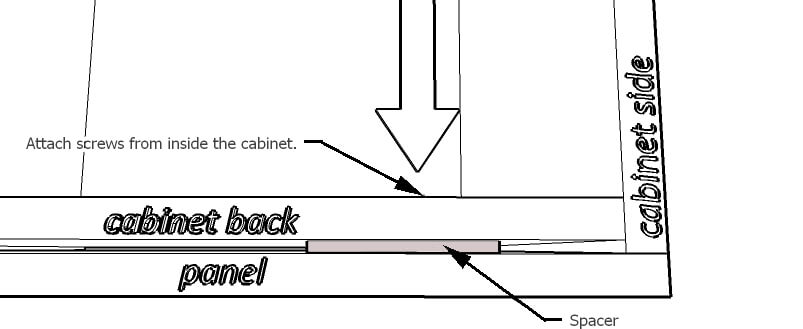

Finished Back Panels

Within your supplied hardware bag, look for the hardware labeled “Finished Back Hardware”.

The finished back hardware consists of:

- Short Screws – 7/8” Flat head screws – Use these to hold the spacers in place.

- Long Screws – 1 1/4″ Pan head screws – Use to hold panels in place fastening from the INSIDE of the cabinet. Do not screw into the face of the back panel. It is very important that you use the supplied screws that are the proper depth for securing the panel.

- Quarter-Inch Spacers – These are used to fill the void between the cabinet’s back and the decorative/finished back panel. One side has beveled holes to countersink the short flat head screws.

NOTE: Always pre-drill holes for screws with a 1/8 inch bit. This will relieve pressure around the screw and prevent potential cracking or splitting of panels over the seasons as the material expands and contracts with temperature changes. It is necessary to maintain warranty coverage that you pre-drill all holes.

- Reference your design to help you find the correct panel location

- Attach spacers to the back side of the cabinet by predrilling with a 1/8” bit, then fasten using 7/8” flat head screws. Face the countersunk side away from the cabinet. Use 2 to 4 spacers per cabinet.

IMPORTANT: IF YOUR BACK PANEL HAS AN UPGRADED COVE OR GROOVE DESIGN, PLACE SPACERS WHERE SCREWS WILL NOT POKE THROUGH THE DESIGN.

- Drill one 1/8 inch hole through each spacer

|

- Use clamps to hold the panel in place, protecting the finished surface of the panel.

- From the INSIDE of the cabinet, through the clearance holes you just drilled, pre-drill partial 1/8 inch holes into the back panel. Do not drill all the way through the panel. Holes should go 1/2 inch into the 3/4 inch back panel.

IMPORTANT: USE A DRILL STOP FOR PRE-DRILLING HOLES IN PANELS. YOU CAN’T PLUG OR FILL A HOLE IN THE HDPE PANEL, SO BE VERY CAREFUL TO NOT DRILL ALL THE WAY THROUGH THE PANEL.

- Use the 1-1/4 inch pan head screws, secure the panel from the inside of the cabinet through the holes you drilled.

|

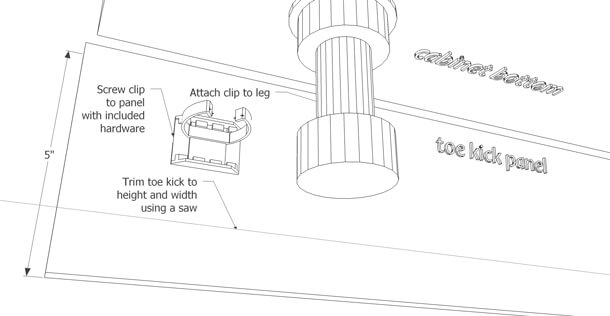

Toe Kick Panel

Once your cabinets are installed, optional toe kick panels can be added. For easiest cleaning and maintenance, you may consider omitting toe kick panels, allowing complete access underneath your outdoor kitchen for vacuuming or hose-washing. Toe kick panels can always be ordered and installed after the project is completed if you want to decide later if toe kick panels should be used.

Trim the toe kick to height and width with an ordinary woodworking saw. Screw the supplied clip panel to the toe kick panel. Attach the clip to the leg.

Insulating Jacket Installation

Insulating jackets for grills are generally one of two different styles:

- Countertop supported with a flange

- Square edged, flange-less, supported from beneath

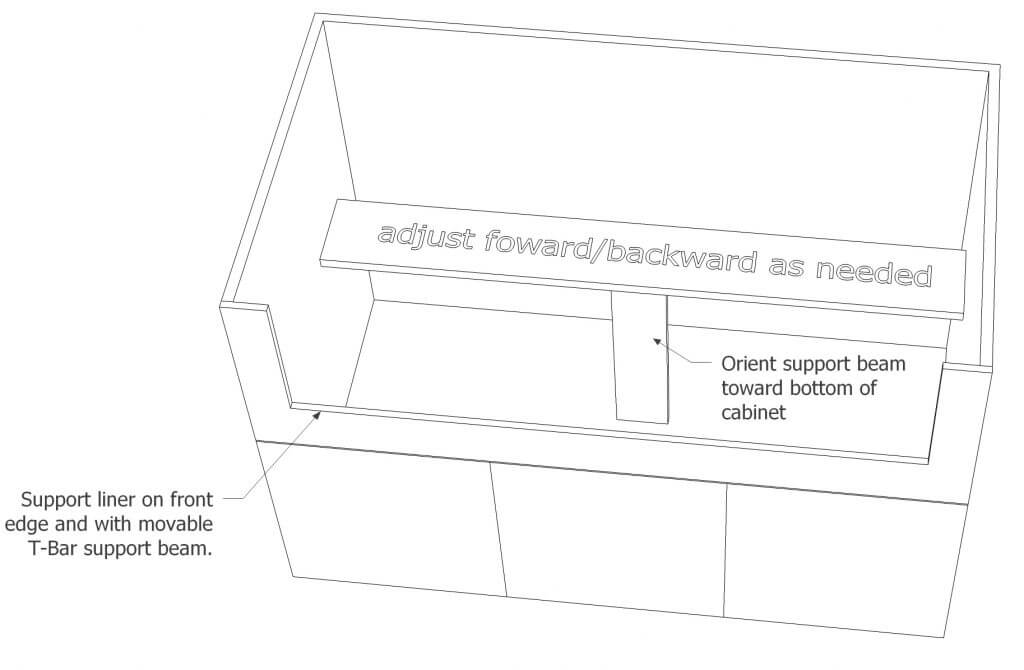

Countertop supported liners have a stainless steel flange that rests on the countertop. They are designed to support the entire grill without any additional support. You may prefer to use the T-bar brace for added support. Square edged, flange-less liners are supported by the T-Bar brace and also rest on the front edge of the grill cabinet. (See diagram below for more information about T-Bar Braces)

Grill Cabinet T-Bar Brace Installation

Wall Cabinet Installation