A builder found out that hard way that not all HDPE cabinets are created equal. He’d started an outdoor kitchen project using another HDPE cabinet, because he thought all HDPE cabinets were the same (hey, at least he didn’t go with PVC). But a short while into the project, he realized that he couldn’t deliver his promise of quality to his client, and called in Werever to fix his problem. Our first order of business – uninstalling the “other” cabinets. We’ll call them ‘Brand X.’

But are all HDPE cabinets the same? What distinguishes Werever Outdoor Cabinetry?

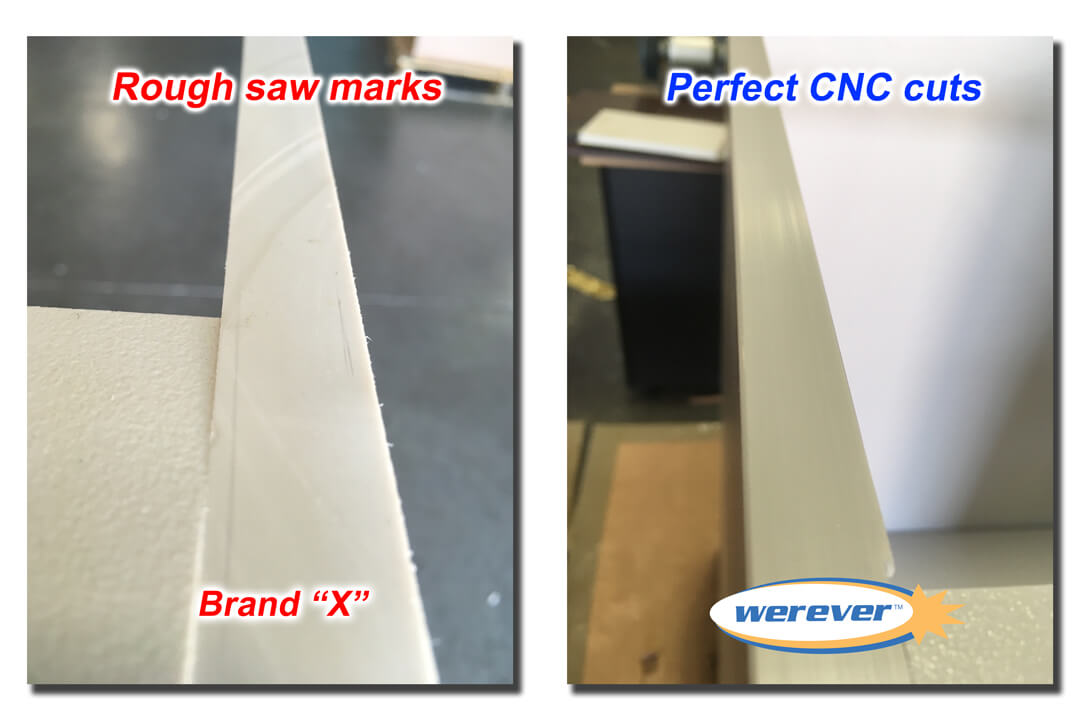

These Brand X cabinets have saw marks. Why is that bad? For one thing, it shows a lack of precision. Are they really 35-3/16 of an inch (or whatever you need your cabinets to be)? It can also lead to burring, which can leave you with painful splinters. And those saw marks are just plain ugly. Werever solved this with precision-machined panels and doors have perfectly smooth edges and corners, to your specifications within 1/1000th of an inch.

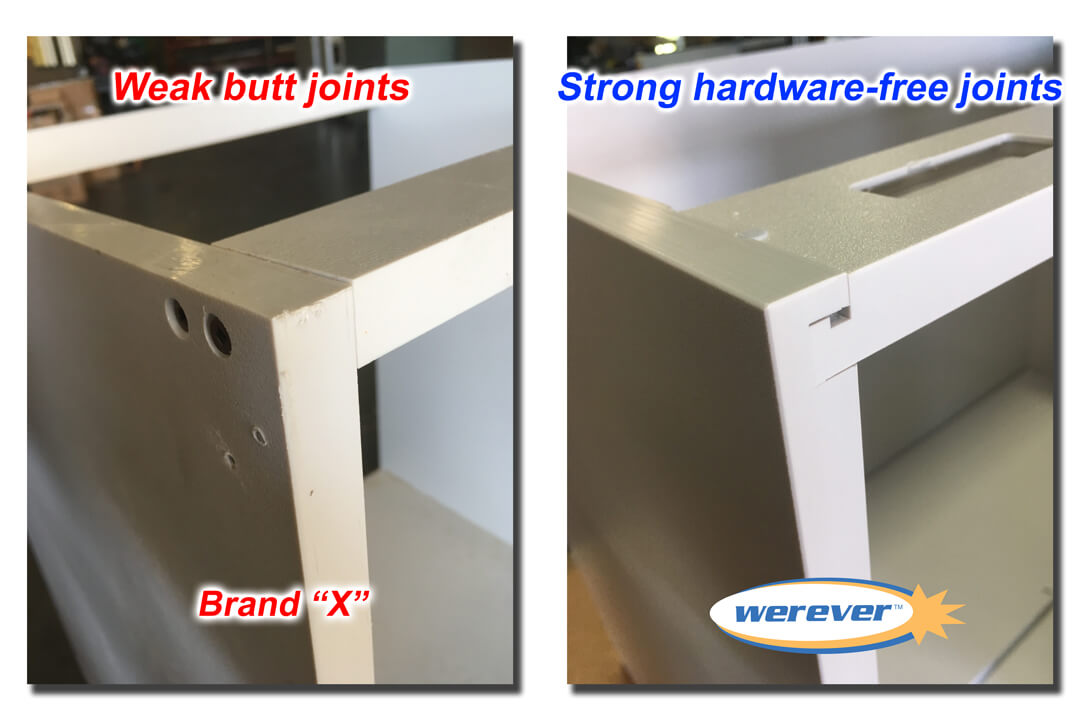

Butt joints held together by screws – those are invariably going to fail and your cabinets are going to warp. Why? Because any material left outside — doesn’t matter if it’s HDPE, PVC, wood or metal — is going to react to temperature changes. The holes where those screws live are going to change shape, the screws will loosen, and the boards will come lose and/or separate. Or the screws will just plain break under load. Werever has overcome that problem with a system we developed. Werever’s hardware-free joint expands and contracts at the same rate since it is made of one material. The joint has been engineered to withstand extreme temperature changes with the right balance of forgiveness and tightness of fit.

Check out Brand X’s supports. Are those going to be strong enough to support your $4000, 300-lb grill? Will they support that heavy slab of granite that costs more than your kid’s first semester at college? Will it support your friends leaning or sitting on your countertop? We know this all happens in the real world, and we have engineered our cabinets to handle it.

When you’re considering your options for outdoor cabinetry, take a close look at details like this. It is true that differing brands of outdoor cabinetry can look very similar from 10-feet away. These differences in construction will absolutely impact the longevity of your outdoor kitchen and the fit-and-finish of the installation.

For more on Werever’s construction, check out Werever’s process and how Everything is Custom. For more information on why HDPE is a superior material than PVC for building outdoor cabinets, check out HDPE vs VC Strength Tests and HDPE vs PVC Heat Tests